How we make an impact

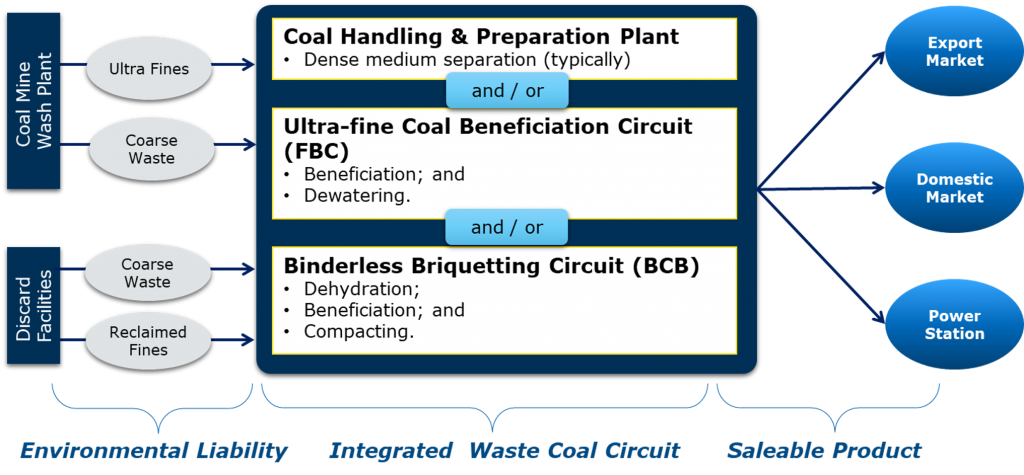

RESA has the capability to deploy and operate the appropriate equipment as an integrated circuit, or as individual components, as required, to reduce rehabilitation liabilities and to maximise yield from coarse and/or ultra-fine waste

Coarse Waste Beneficiation

Ultra-Fine Coal Solution

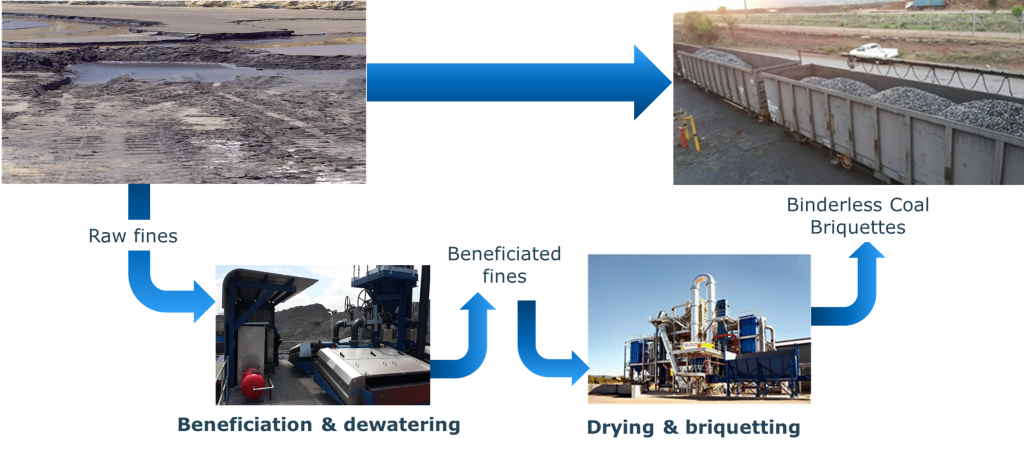

Typical upgrade of slurry that is achievable from high moisture arising fines and reclaimed fine coals found in SA coalfields, results in the production of low moisture, export specification coarse product.

Ultra-Fine Coal Benefication

Proprietary Systems

The fine coal recovery plants are designed to:

- Intercept waste slurry arising from the coal processing activities using circuits with a low operational cost.

- Separate product (oversize) from discard.

- Remove significant quantities of the material from the waste slurry.

- Significantly reduce the amount of make-up water required for the processing of coal.

- Dewater the upgraded product to <15% TM.

- Deliver a high value, beneficiated fine product ideal for blending and the production of constructed coal.

Binderless Coal Briquetting

Patented Technology

- Binderless Coal Briquetting (“BCB”) is a patented technology developed by a consortia led by the CSIRO over 20 years and refined and commercialised under an exclusive global license

- The BCB technology was developed to upgrade low-value/waste coals through a low-cost process of dehydration and compaction

A Proven Technology

- We have invested since 2009 in proving this technology in SA and testing on numerous sources of fine coal.

- Very positive results from combustion and materials handling tests.

- This has provided a platform for the recovery, beneficiation & upgrading and briquetting of coal without a binder.

- Our BCB product:

- No binder/additives

- A consistent burn profile

- No effect on the volatiles

- No effect on the ash content

- Can be produced from wet feed material

We have proven the beneficiation and BCB technologies on SA fines coal for the production of constructed coal.

We enjoy a strong market position as a unique cleaner coal transition technology.